RCO catalytic combustion equipment

RCO catalytic combustion equipment

Detail

劲旅环境

The catalytic purification device mainly uses catalysts to change reaction conditions to achieve the removal of organic matter under lower conditions. The essence of the gas-solid catalytic reaction occurring in the catalytic purification device is the deep oxidation effect of active oxygen species.

Industry applications:

1. Waste gas treatment in industries such as petrochemical, chemical, pharmaceutical, surface coating, automotive manufacturing, printing and dyeing, packaging and printing, furniture manufacturing, etc.

2. Where catalytic combustion technology is not suitable: waste gas containing CI, S, Br, P, Si, heavy metals, etc., which may cause catalyst poisoning

Equipment features:

Our company's products have the following characteristics: they can be ordered and selected according to the actual situation of customers

1. Convenient operation: Automatic control is achieved when the device is working.

2. Low energy consumption: When the equipment starts, it only takes 15-30 minutes to warm up to the ignition temperature. When the concentration is high, the energy consumption is only the fan power, and when the concentration is low, it automatically compensates

3. Safe and reliable: The equipment is equipped with a fire resistance and dust removal system, an explosion-proof and pressure relief system, an over temperature alarm system, and an advanced automatic control system

4. Low resistance and high purification rate: Adopting advanced precious metal platinum impregnated honeycomb ceramic carrier catalyst, with high airspeed.

5. Activated carbon is made of water resistant materials with high density pores and high adsorption rate, which has strong adsorption and long service life. 6. Long service life: The catalyst is generally replaced after 8000 hours, and the adsorbent is replaced after 1-2 years

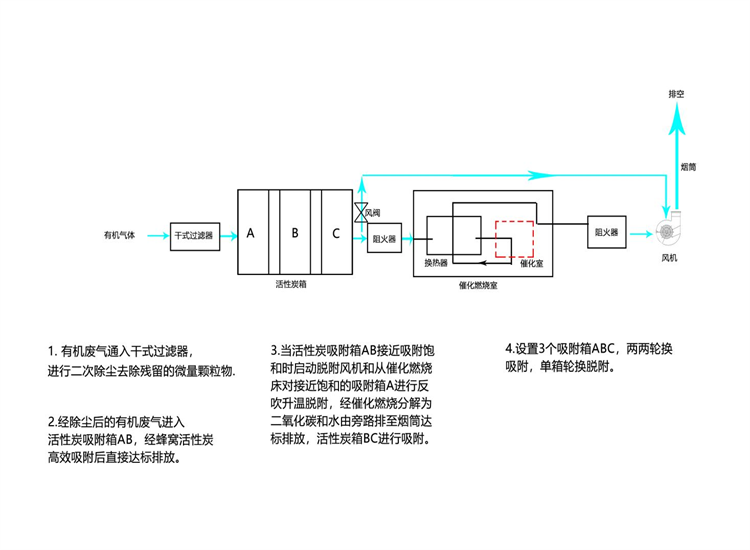

Equipment principle:

Catalytic combustion method uses catalysts as intermediates to convert organic gases into harmless water and carbon dioxide gases at lower temperatures, namely CnHm+(n+ ¼ m) O2 catalyst/200-300 ℃ nCO2+ ½ MH2O utilizes a catalyst to cause flameless combustion of the exhaust gas at lower ignition temperatures, and oxidizes and decomposes it into harmless CO2 and H20, releasing a large amount of heat energy, thereby achieving the goal of removing harmful substances from the exhaust gas.

|

|

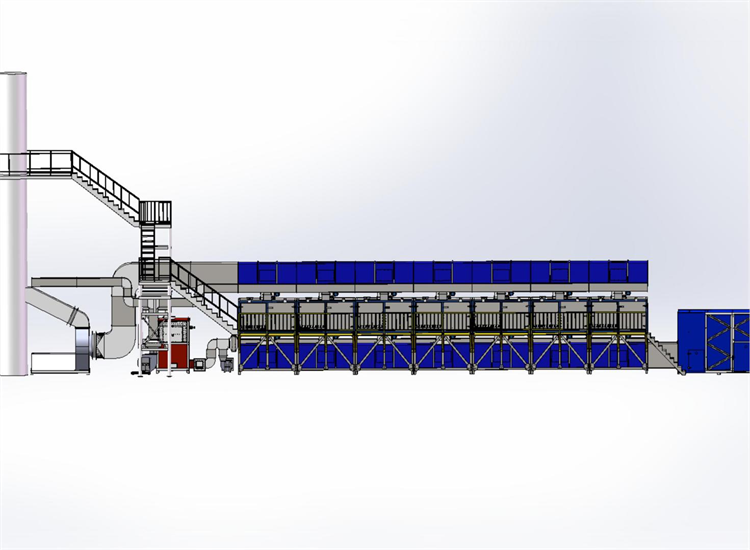

| Catalytic combustion schematic diagram | Catalytic combustion assembly diagram |

Engineering case:

|

|

|

| Hangxiao Steel Structure (Hebei) Construction Co., Ltd. 100000m ³/ H Activated carbon adsorption+catalytic combustion equipment | Lipang Coatings (Henan) Co., Ltd. 80000 meters ³/ H Activated carbon adsorption+catalytic combustion equipment | Tianjin Jingtong Pipeline Technology Co., Ltd. 60000 meters ³/ H zeolite molecular sieve adsorption+catalytic combustion equipment |

Related products

Feedback

COPYRIGHT Tangshan Lantian Aoyu Technology Co., Ltd Powered by 300.cn | SEO

Zero discharge of wastewater

Zero discharge of wastewater Service guarantee

Service guarantee Qualification certificate

Qualification certificate +86-15203250555

+86-15203250555